Stevanato(OMPI) Nexa® Vials 西林瓶具有卓越的機械阻力,可提高效率和安全性

廠商名稱:昱新先進股份有限公司

發佈日期:2025-05-22

攤位號碼:M1011

JAN 8 | 2025

The Superior Mechanical Resistance of Nexa® Vials for Improved Efficiency and Safety

Executive Summary

Introduction: Ensuring the mechanical resistance of pharmaceutical glass vials is crucial for safe and efficient drug delivery. While allowing for high throughput and efficiency, the bulk Fill & Finish process exerts high level of stress on glass containers, such as glass-to-glass contact and vertical loads, which can lead to cosmetic defects and breakages. Superior vial quality mitigates the negative impact of this stress, improving filling process performance and output as well as reducing the risk of container breakage during transport.

This study aims to experimentally demonstrate the improved mechanical resistance performance of Nexa®. By comparing the 2R ISO format vial in Nexa® and Fina® platforms, this study highlights how Nexa® vials provide superior mechanical resistance, which translates into several operational benefits.

Test Methodology

Mechanical resistance was assessed using two quantitative techniques

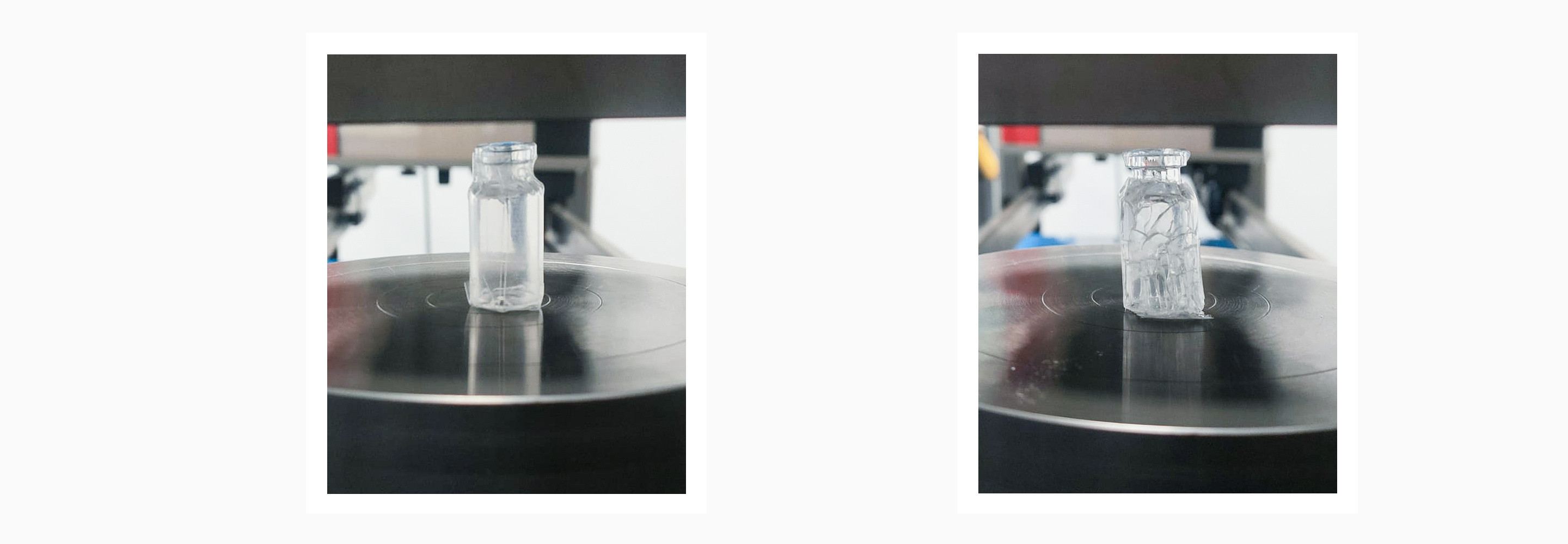

1. Vertical Compression Test (VC): This test measures the maximum force a vial can withstand before failure when subjected to axial stress.

Figure 1: Sample before (left) and after (right) VC test.

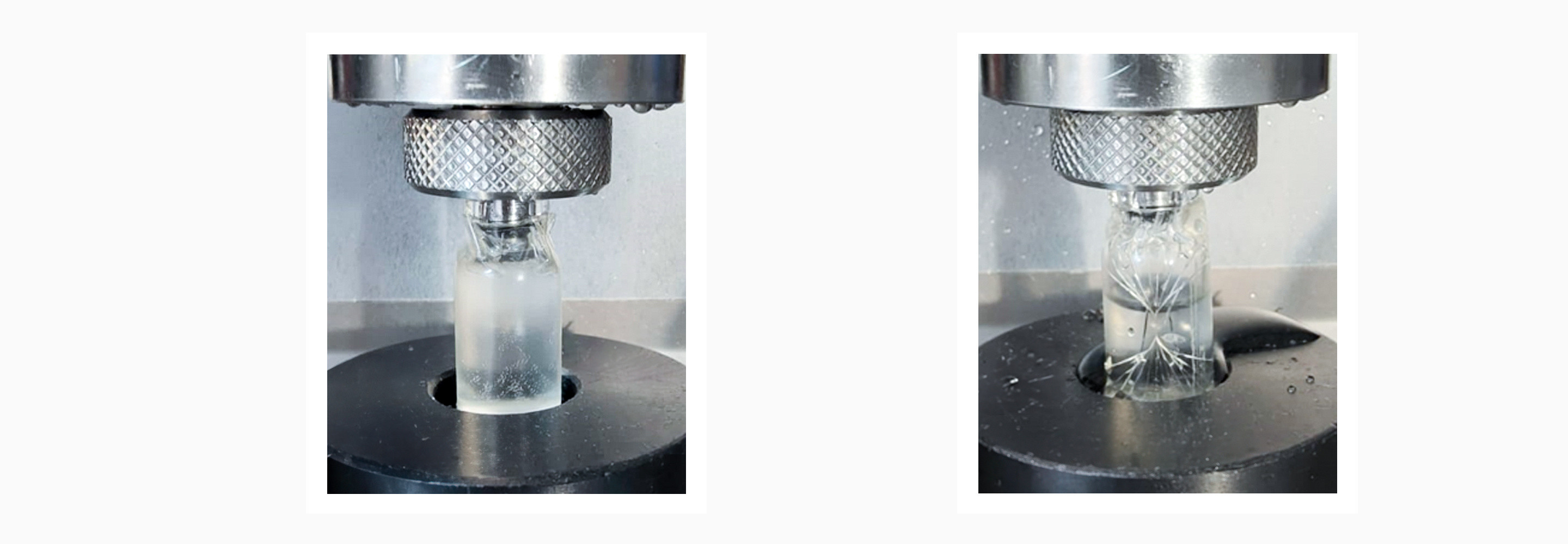

2. Burst Test (BT): This test is performed to apply internal pressure to the glass container to obtain its maximum value of internal pressure resistance.

Figure 2: Sample before (left) and after (right) the burst test.

Both tests compared Nexa® and Fina® vials. From the results achieved (VC and BT), Nexa® vials showed consistent superior mechanical resistance.

Key Results

2R ISO vials

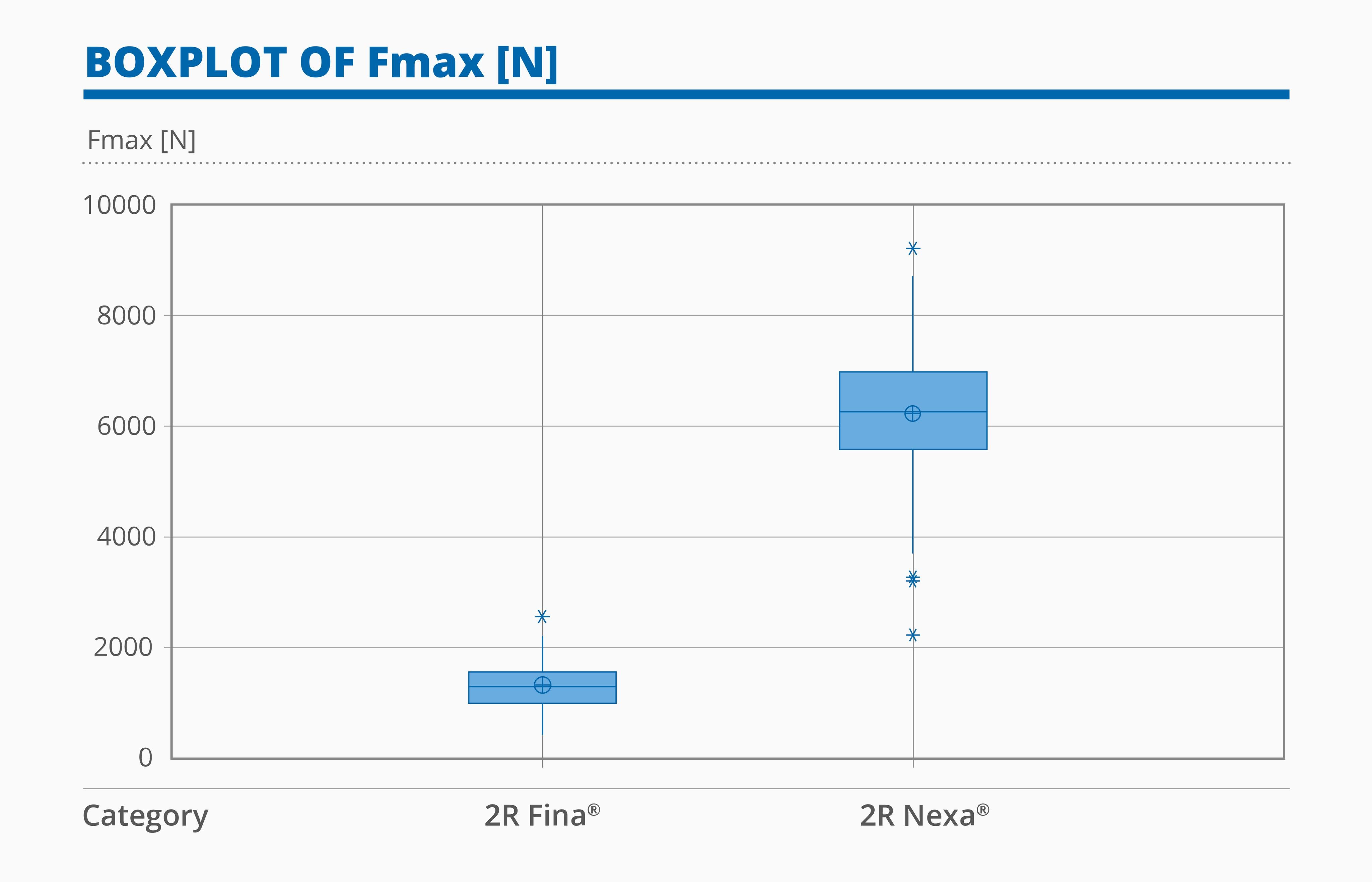

- In the Vertical Compression Test, Nexa® vials demonstrated an average maximum force of at least 3x Fina®.

Figure 3: Boxplot of Vertical Compression results for 2R Fina® and Nexa® vials.

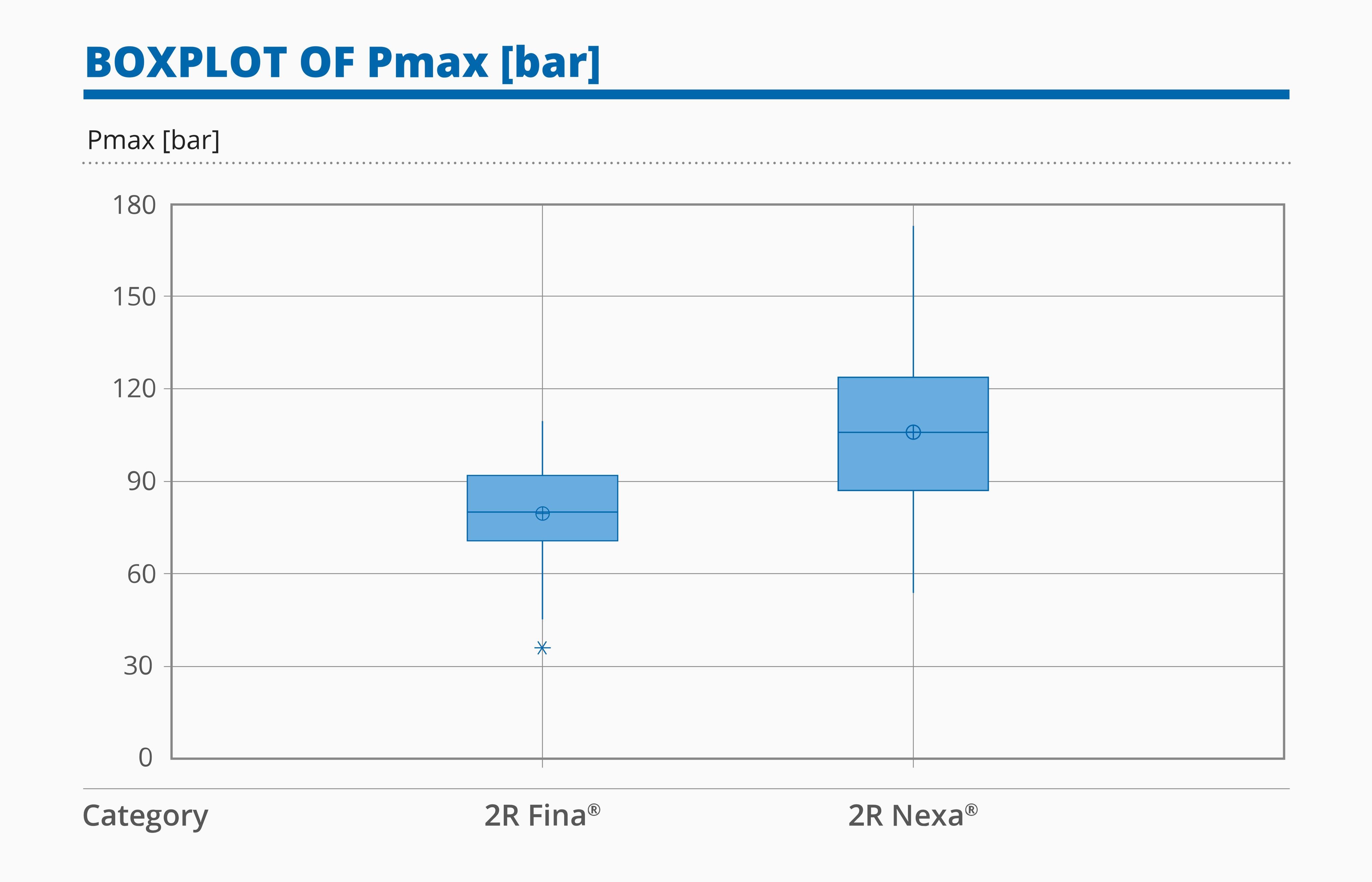

- In the Burst Test, Nexa® vials are characterized by a higher mean value, in terms of maximum pressure, than Fina® vials.

Figure 4: Boxplot of Burst Test Results for 2R Fina® and Nexa® vials

Operational Benefits of Nexa® Vials - Thanks to their improved cosmetic quality and mechanical resistance, Nexa® vials provide several advantages:

01 Reduced Total Cost of Ownership (TCO): Fewer cosmetic rejections and in-line breakages reduce waste of both container and final product, which in turn lowers costs and prevents lost revenues.

02 Improved Efficiency: Nexa® vials result in fewer lines-stops, downtimes, and labor required to fix the filling line after breakage occurrence.

03 Higher Safety: The superior mechanical strength of Nexa® vials reduces the risk of harmful products being dispersed due to container breakage.

Conclusions

This study analyzed the improved mechanical resistance of Nexa® vials by comparing them to Fina® vials through vertical compression (VC) and burst test (BT). According to the results achieved, Nexa® vials have superior mechanical resistance, even 3x Fina® with regards to Vertical compression (VC).

Thanks to its improved mechanical resistance, the Nexa® vial platform offers advantages in terms of:

01 Lower risk of breakage and cosmetic rejections reducing non-quality costs, and maximizing redictivity of high-value drug products

02 Lower risk of breakage to preserve people’s safety when dealing with cytotoxic products and to guarantee container integrity during challenging freezing processes.

Nexa® vial platform is Stevanato Group next level of quality specifically designed for most of high value products such as biotech, high-value vaccines, cytotoxic and next generation drugs.

Thanks to their improved mechanical resistance and cosmetic quality Nexa® vials minimize product waste and product release into the environment during fill & finish process and final visual inspection.

Additionally, Nexa® vials ensure lower vial breakage risk at challenging temperatures during freezing and cryo treatments.

更多參展商新聞稿

- 國鼎生技推進全球三期臨床在轉移胰臟癌一線治療 國鼎生物科技股份有限公司 / 2025-09-11

- 潤霈生技亞洲生技大展首度登場 眾多明星商品強力吸睛引爆熱潮 潤霈生技股份有限公司 / 2025-08-20

- IOT無線連續監測系統 - 廠房、倉儲、實驗室 溫、濕度測繪 幸託有限公司 / 2025-08-20

- 現場校正、抽檢應用 攜帶式測量儀 幸託有限公司 / 2025-08-07

- 鴻曜醫學取得生技醫藥產業發展條例資格審定 深耕台灣、邁向國際臨床規範 鴻曜醫學股份有限公司 / 2025-07-30

- 突破性幹細胞療法!鴻曜醫學MiSaver ⼼肌梗塞後修復效果顯著 鴻曜醫學股份有限公司 / 2025-07-30

- 鴻曜醫學邁向國際:幹細胞療法 MiSaver® 啟動跨國臨床試驗,打造心血管再生醫療新藍圖 鴻曜醫學股份有限公司 / 2025-07-28

- 思必瑞特生技首次亮相BioAsia!關鍵凍晶技術實現PRP精準醫療 思必瑞特生技股份有限公司 / 2025-07-28

- 賽博生醫攜手捷昇生物科技 引進RASTRUM™加速3D細胞列印與癌症藥物開發 賽博生醫股份有限公司 / 2025-07-27

- 賽博生醫推出FormuGel™ 3D細胞培養膠體平台,整合腫瘤建模×藥效分析×科研服務 賽博生醫股份有限公司 / 2025-07-26

- 賽博生醫攜手成大比較醫學研究中心 打造高通量高擬真的3D腫瘤藥篩平台 賽博生醫股份有限公司 / 2025-07-26

- 啟弘生技與AAVnerGene攜手合作下世代腺相關病毒(AAV)載體製程研發 啟弘生物科技股份有限公司 / 2025-07-25

- 7/24-7/27 GBC普生在 亞洲生技大展 與您相見 普生股份有限公司 / 2025-07-25

- 普生GBC CellBio™ a2000 榮獲2025愛迪生獎肯定 普生股份有限公司 / 2025-07-24

- 普生竹創大樓開幕啟用 AI精準醫療、大健康佈局再升級 普生股份有限公司 / 2025-07-24

- 誠邀蒞臨|4樓M412 展位「多家廠商聯合座談會」,精彩不容錯過! 利政科技股份有限公司 / 2025-07-24

- 中宇環保工程股份有限公司:生技製藥建廠與製程設備整合專家 利政科技股份有限公司 / 2025-07-24

- 專業實驗室儀器製造商- major science 利政科技 利政科技股份有限公司 / 2025-07-24

- 生展生技應邀參加 Bio Asia 2025 三大創新產品搶攻亞洲保健市場新藍海 ! 生展生物科技股份有限公司 / 2025-07-24

- 銳準生醫全新發布髓易測MyeloTrak™,以非侵入精準檢測革新多發性骨髓瘤管理 銳準生醫股份有限公司 / 2025-07-23