An Introduction to the agglomeration of the particle using Taylor Flow

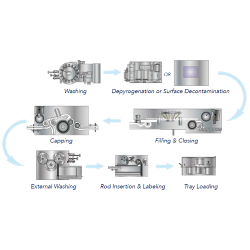

Model: LCTR

Category: Pharmaceutical Equipment

Exhibitor: EUFLEX TECHNOLOGY CORP.

Booth No: L408

Characteristic

There are many types of reactors in industry, the most common types are tank (CSTR) and tubular (PFR) reactors, both of which can be operated continuously or in batches. In theory, a PFR is more efficient than a CSTR at the same working volume; in other words, given the same residence time, the material reacts to a much greater extent in a PFR than in a CSTR. However, CSTRs are more commonly used in many areas.

Taylor Flow Reactor and Its Technical Principle

The Taylor Flow reactor is designed to overcome the challenges of traditional PFR. It utilizes dynamic mixing rather than the static mixing used in conventional PFRs, while also allowing for controlled agitation speed. The Taylor Flow reactor is a special reactor that generates a "Taylor Vortex" when a fluid flows in the gap between two different cylinders with the same center line and the inner cylinder rotates at a constant speed. Under certain conditions, if the rotation speed of the inner cylinder exceeds a critical value, the flow becomes unstable and then generates a pair of rings rotating in opposite directions along the axial direction.

Taylor reactors allow for easy control of particle characteristics

For the production of particles such as ammonium perchlorate (AP), tank reactors have difficulties, such as difficulty in obtaining spherical particles or porous particle surfaces without additives. Taylor reactor can easily solve these problems. In a supersaturated solution, the particle formation process is first nucleation, then crystal growth, followed by particle agglomeration and fragmentation. By understanding this mechanism, the particle size and shape can be controlled by controlling parameters such as rotation speed, residence time, and the size of the gap between the inner and outer cylinders.

Feasibility for mass production:

Compared with traditional tank reactors, Taylor reactors are easier to scale up. Traditional tank reactors can take at least a month or a year or even longer to scale up because the flow changes when the tank volume is increased. However, when scaling up a Taylor reactor, similar particle size and shape can be produced with a larger reactor size as long as the same Taylor number and linear velocity are matched.

Since there is no mixing between each Taylor vortex, each Taylor vortex can be regarded as a trough reactor. For example, a Taylor reactor with a working volume of 1000 liters has 14 Taylor vortices under certain parameters and can be regarded as 14 71-liter trough reactors connected in series. It is obviously much easier to scale up from 1 liter to 71 liters than from 1 liter to 1000 liters.

Laminar has commercialized the Taylor reactor through its patented design, providing both laboratory-scale and commercial-scale reactors.

Other Products

Products you may be interested in

Highest Rated Products