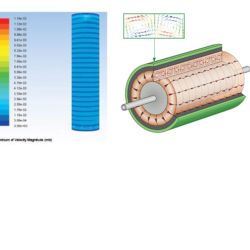

Crystallization Process Optimization using Taylor Vortex Flow

Model: LCTR

Category: Pharmaceutical Equipment

Exhibitor: EUFLEX TECHNOLOGY CORP.

Booth No: L408

Characteristic

Shionogi Pharma of Japan uses Laminar’s Continuous Taylor Reactor (LCTR®) technology to optimize its API (active pharmaceutical ingredient) crystallization process. The core goal of the research is to use the Taylor reactor (LCTR®) to directly synthesize particles with specific properties and appropriate size distribution, thereby eliminating the subsequent milling process. This study used the LCTR® - Lab II-V reactor to conduct a study including seed crystallization/anti-solvent processes to explore the changes in seed number and particle size. After reaching a steady state, samples were taken to analyze the particle size and distribution.

Result

• Successful preparation of crystals ranging from 3.0 to 29.7μm with 90% particle size and particle

size equivalent to milled product.

• Parameter studies and scale-up examinations confirmed the importance of shear force over the

Taylor number.

Key findings

1) Controlling shear force had a greater impact on achieving desired particle size and distribution.

Shear force influences particle interaction and formation during crystallization. Optimizing shear

force results in more uniform and controlled particle sizes.

2) The Taylor number (Ta) in a Taylor Vortex Reactor is a dimensionless number that characterizes

the flow stability between two rotating cylinders, which can be optimized for specific

crystallization reactions. Taylor number affects flow.

Other Products

Products you may be interested in

Highest Rated Products